A short list of questions that keep popping up at Guitar Mill Luthier Shop. For information on lead/wait times CLICK HERE!

Q: How does Guitar Mill finishing and aging compare to other finish and relicing services?

A: The Nitrocellulose finishes and aging/relic work that Guitar Mill Luthier Shop does are highly regarded as some of the best in the business. We have the experience and skill to spray over 100 different colors. Our expertise is not limited to only reliced/aged finishes either — we can produce a new showroom-quality, pristine finish or one that looks to be 50 years old. Aging is emerging in popularity, roughly 75% of customers request our relic/aged finishes; a dramatic increase from even a few years ago. Guitar Mill has become known worldwide for our highly realistic aged nitro finishes.

Our specialty is aging which looks natural, believable, and tasteful – Our relics never look like a parody of a vintage guitar. Our relics look like the real deal. We even own TWO industrial spray booths: one for solid, candy, and trans finishes and one for flake!

Q: Will You Guys Drop Ship To Another Finisher To Have My Body / Neck Sprayed There?

A: NO (See Above, How Our Finishing / Aging Work Compares To Others!

Q: Can Guitar Mill match a color? I have an image I can email over for reference.

A: The answer to this one is more complicated than it would seem. The short answer is – Yes, we can color match for an additional upcharge fee of $150.00. The main issue with using an image displayed on a computer, phone, etc.. to match a specific color is that the color will be displayed differently on different devices. For instance, a particular shade of color will vary from what you are seeing on your monitor / phone , to what we are are seeing on our end. So, even though we can somewhat get the idea of what you are wanting, please be aware that unless we have a physical item or color swatch on hand, there is really no way that a color can be 100% accurately matched by looking at a screen / monitor.

Q: Why should I choose a Guitar Mill body?

A: Guitar Mill bodies are cut using hand-selected premium woods. We’re known also for having the highest-grade lightweight swamp ash and solid, beautiful alder available.* Our master grade Paulownia/Empress Wood is something that no other company has been able to consistently offer, but this tonewood allows us to make guitars that are some of the lightest in production.

Spending over fifteen years in the guitar repair business has had its perks. Meaning, we’ve had tons of vintage guitars in the shop, and many customers have graciously allowed us to “Clone” those vintage instruments. This has given us the ability to build and offer the most vintage-correct versions of the classic body shapes.

*Alder availability is subject to market. Light-weight, trans-grade or 1 pc. alder may be back-ordered — contact us for availability.*

Q: Where is your physical location? What are your hours?

A: We are located at:

407 W. Lytle St.

Murfreesboro, TN

37130

Our hours of operation are:

Monday – Friday: 11 A.M. – 6 P.M.

Saturday by appointment only.

Closed Sunday.

Q: Why is this item in “Get it Now?” Is there something wrong with it?

A: “Get it Now” is simply the online store portion of our business. Most all of the items in the “Get it Now” store are the same “A-Stock” quality you have come to expect from Guitar Mill Luthier Shop — they just happen to be in-stock and ready-to-ship. We make bodies and necks with the explicit purpose of selling them in our “Get it Now” store nearly every week. If you are looking to custom order a new body or neck, “Get it Now” is the first place to check! “Get it Now” and custom ordered products will be the same quality, so why not skip the wait? All items that are ugly/heavy/damaged/etc. are in our “B-Stock” or “Clearance” sale sections. These sale section items are clearly labeled in the title of the product and the reason for “B-Stock” or “Clearance” classification is ALWAYS explained in the product description. Feel free to Contact Us if you have any questions on the differences between these sections, or if you have questions about a specific item!

Q: If I purchase Guitar Mill parts, how difficult will my final assembly be?

A: As a business that often caters to hobbyists and beginning luthiers, we get asked this question quite frequently. The difficulty of a build is completely contingent on what style of guitar you are building and the attention to detail you put into it. Difficulty levels for each style are as follows:

- T-Style: For beginning and novice luthiers. The T-Style was one of the first electric guitars ever designed. Its elegance and versatility are complimented by its beautiful simplicity. We recommend everyone build a T-Style while beginning luthiery; it is the best style to hone your technique. After all, that is how we got our start; the first guitar assembled by Mario Martin was a T-Style.

- S-Style: For adept luthiers. The S-Style was created to improve upon issues found in the T-Style. Designed with comfort in mind, the S-Style has become one of the most popular guitars in the world. That being said, its more complex tremolo system and electronics make the S-Style is a bit more complicated than the T-Style. S-Styles still make good first builds, but are not as simple as T-styles.

- JM-Style: FOR EXPERIENCED LUTHIERS ONLY! We love the JM-Style. It is a beautiful sounding, classic instrument. That being said, its beauty and tone is directly related to the instrument’s complicated nature, therefore, it is maybe the most difficult build that we offer. Designed with the musical complexity of jazz in mind, the JM’s circuitry and tremolo systems are far more advanced than those of the other models. Additionally, JM parts are made by an assortment of different manufacturers, making minor (but crucial) discrepancies in alignment quite common and frustrating. If you are considering a JM build, be sure you know exactly what you are getting yourself into, otherwise we highly recommend that you leave the assembly to us.

- JAG-Style (and Stang-Style): For adept to expert luthiers. The Jag-style is one of the most modular guitars when it comes to tone. Its short scale makes it a prime beginner guitar, or good for those with smaller hands. However, it is only slightly less complicated than the JM. The Tremolo system of the Jag is like the JM, and the circuitry may be even more complex. Additionally, Jags have several separate control plates that can be difficult to align just so. Don’t fear building a Jag, we just wouldn’t recommend starting your luthiery career with one.

- T-Master: For beginning to adept luthiers. After becoming one of the most sought-after mash-up designs in electric guitar history, the T-Master is one of the coolest guitars that has never seen mass production. Though it shares many aspects of the JM, the T-Master is more akin to the T-style when it comes to assembly and set up. If you are looking for a really unique first build, the T-Master is perfect for you.

- Basses: For beginning to adept luthiers. Bass models are usually a lot easier to build and set up due to the relative simplicity of design and circuitry. P-Style basses are on par of design simplicity with T-Style guitars, and Jazz-Style basses are only slightly more complicated than that. If you like to play in the low end, then building a bass is not a bad place to start your luthiery career.

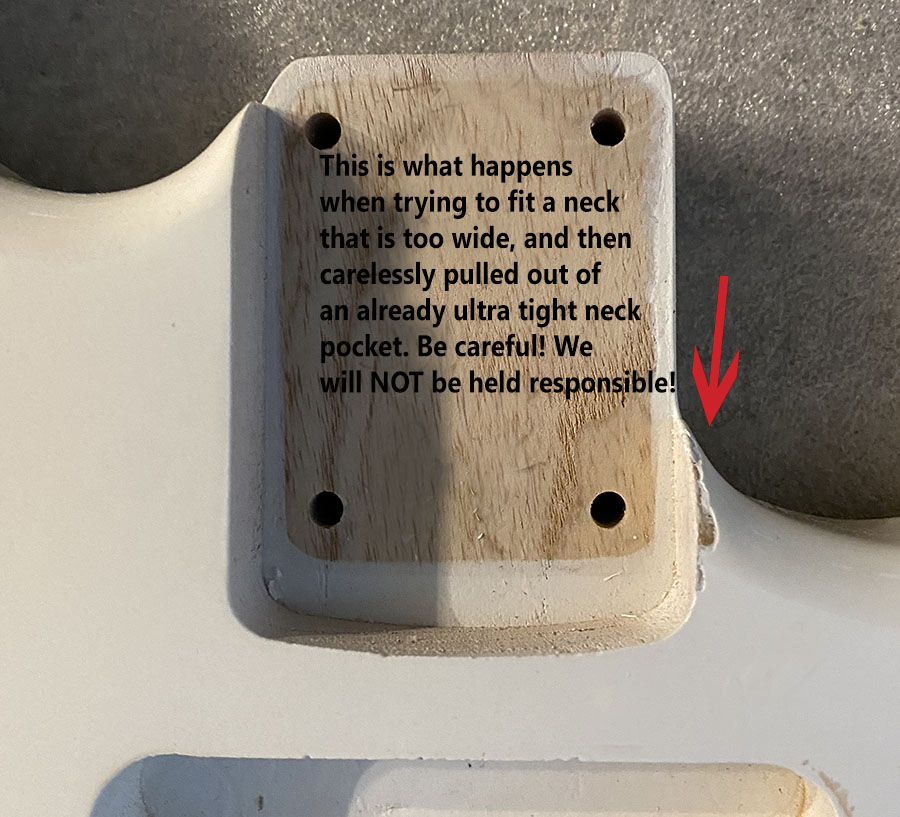

PLEASE NOTE: Guitar builds are not like Lego® sets. Pieces don’t always fit together perfectly right out of the box. Chances are, your accessories and hardware will require a bit of alteration, alignment or mild adjustment to fit together into the best product possible. We make our parts to be compatible with Fender® licensed “American Vintage” or “AVRI” parts, but we cannot guarantee that our guitar parts will work with any other manufacturers’ accessories. Guitar Mill is not responsible for these mild discrepancies and all refunds provided on this basis will be subject to our 30% restocking fee (See last question on page for more info on restocking fees) — if they are refunded at all. As always, we recommend consulting an experienced luthier before all major builds.

Q: What hardware do I need to buy for my Guitar Mill build?

A: Guitar Mill bodies and necks are built to American Vintage specifications. Hardware manufacturers and other parts/guitar builders have a number of different nomenclatures they use to market these parts, but 99% of the time, if hardware is marked “American Vintage,” “AVRI,” “American Vintage Reissue,” “American Original” or “19XX Reissue” it will fit our parts with little to no adjustment needed.

DO NOT buy the “American Standard,” or the “Fender Standard” as those will not fit. “American Standard” is modern spec, and the “Standard” is import (Mexico, Japan) spec.

We know that due to the sheer volume of aftermarket parts available, these options can be overwhelming, but tune in to the keywords “Vintage” or “Original” and your hardware should fit, no problem!

Q: I checked on my body 2-3 weeks ago and it is in the same point of production, what gives? Did you forget about me?

A: Our orders are processed in batches. At any given time, we have ~250-300 or more bodies and necks on order (including full builds.) The filling, sealing, priming, sanding and other prep work in finish of any given body or neck makes up about 75-80% of all time spent in finish. Once the body is primed and completely level sanded, the 1-2 coats of color and 1-2 coat of clear for standard colors, necks and bursts go fairly quickly. Once your first coat of color is sprayed, it only takes about 2-3 weeks to finish the job.

Since the orders are done in batches, there may be periods of time where your body is curing or waiting for the next step, so it may not physically progress much between “check-ins.” This means that we do not work on every individual order every single day. This is not an indication that we have forgotten about your order or that your order is any further behind than the last time you checked in.

We are only 8 people, and every single finish that comes through the building is handled by Mario personally, thus we are processing these orders in the best way we know how. We appreciate your patience and promise that finished product will be well worth the wait.

Q: I didn’t get my order confirmation or tracking number — what gives?!

A: Be sure to check your “Promotions” and “Spam” folders for any automated messages from Guitar Mill. Gmail and other email carriers will occasionally tag our update emails as “Promotional” and take them out of your main inbox.

Additionally, If you ordered via Paypal Checkout, our system might not send you an order confirmation — as the record of the order is already visible in your Paypal account.

Q: Where do you source your bodies from?

A: We don’t. Every Guitar Mill body is rough cut by CNC and then shaped by hand right here in our 4000 sq. ft. shop in downtown Murfreesboro, TN — about thirty minutes from Nashville.

Q: What is “Polly-ween-yuh?” What are some characteristics of it? Would it be a good choice for me?

A: Paulownia (pronounced “paw-LOH-nee-ə),” also sometimes referred to as “Empress Wood”) is an extremely light-weight tonewood that is perfect for making guitars. Finished Paulownia guitar bodies can weigh as little as two pounds. A finished Paulownia guitar can weigh in at 5 pounds or less. However, unlike basswood or balsa wood, the weight of the wood does not make it an inferior tonewood. It has a tonal quality that closely resembles Ash, if maybe not a bit more resonant. So, if that back is breaking from all those hours on stage, Paulownia is the tonewood for you!

Over the years Guitar Mill has proven to be unmatched in having access to and supplying the absolute most lightweight Swamp Ash available. Our Ultra light weight Swamp Ash remains our biggest seller. Several years ago, in an effort to experiment with an alternate and more sustainable wood, we began using Paulownia. Obviously the tone and resonance of the wood were of the utmost priority, but also being able to obtain a wood that is commercially farmed in our geographic region, was a top priority as well. Thankfully, Paulownia – has been able to fill both of these requirements!

Paulownia or “Empress “wood has the same qualities that have made Swamp Ash such a popular tone wood. Appearance, tone, weight, resonance – Paulownia and Swamp Ash share these highly esteemed traits. As far as differences in the woods go, Paulownia is substantially lighter in weight. The ultra light weight of Paulownia is a result of a tree that grows remarkably fast. Where as an Ash tree may not be mature enough to harvest until 50+ years – a Paulownia tree can be matured enough to be cut in as little as 12 years. Make no mistake; lightweight Swamp Ash has decades of proof that it is a perfect match for electric guitar body wood. This renowned tone wood of the Deep South will continue to reign supreme. Don’t be surprised in the near future when Paulownia takes its place on the list of the most sought after tone woods.

Additional Information on Paulownia: A favorite of surfboard makers, Paulownia remains light weight without sacrificing durability. If your environmentally friendly side is showing, Paulownia is the most “green” tonewood option we offer — Paulownia grows to maturity in 15 years and uses far fewer resources than the Ash or Alder tree, which takes 50+ years to mature. All of our Paulownia is grown right here in the U.S.A., in fact it is grown at the base of the Smokey Mountains in East Tennessee, about a three hours drive from Guitar Mill.

Q: Why should I choose a Guitar Mill neck?

A: The neck is the lifeblood of your guitar; it is the part of the guitar that has the most contact with your body. That is why building a great guitar body is one thing, but being able to build a great neck takes an even greater amount of skill. We are proud to say that we excel in this department as well, and our necks are highly sought after. In the early days, Guitar Mill only offered bodies. We felt that a considerable investment in time and research and development was needed before we were ready to add custom necks to our product line. So after a tough two years of experimenting with a variety of building processes, and constantly referencing genuine vintage necks, we were finally ready for the next phase – CAD / CAM or CNC programming.

The process of computer drawings to CNC router took an additional year of software programming, but the end result has made our necks even more popular than our bodies. We are able to produce a neck that has all of the highly prized vintage-correct characteristics. Right down to the correct vintage skunk stripe size, truss rod & nut placement, 50/50 side dots, clay dots, veneer boards and the list goes on to include every minute detail. We also go the extra mile and precision CNC cut the curved truss rod slot using full 3D geometry and utilize a .2” ball nose bit so that the truss rod fits perfectly in the neck every time. Our frets are CNC slotted using a micro precision bit that follows the 3D radius of the corresponding fingerboard radius. This is a far superior method over simply using straight line saw blades for slots, as most companies do. Just like our truss rods — our frets seat perfectly into each curved slot.

For more info on why you should choose our necks CLICK HERE!

Q: Where do you source your necks from?

A: We don’t. Every Guitar Mill neck is rough cut by CNC and then shaped by hand right here in our 4000 sq. ft. shop in downtown Murfreesboro, TN — about thirty minutes from Nashville. Tim, senior luthier and our neck specialist, has been with us since the beginning of the Mill.

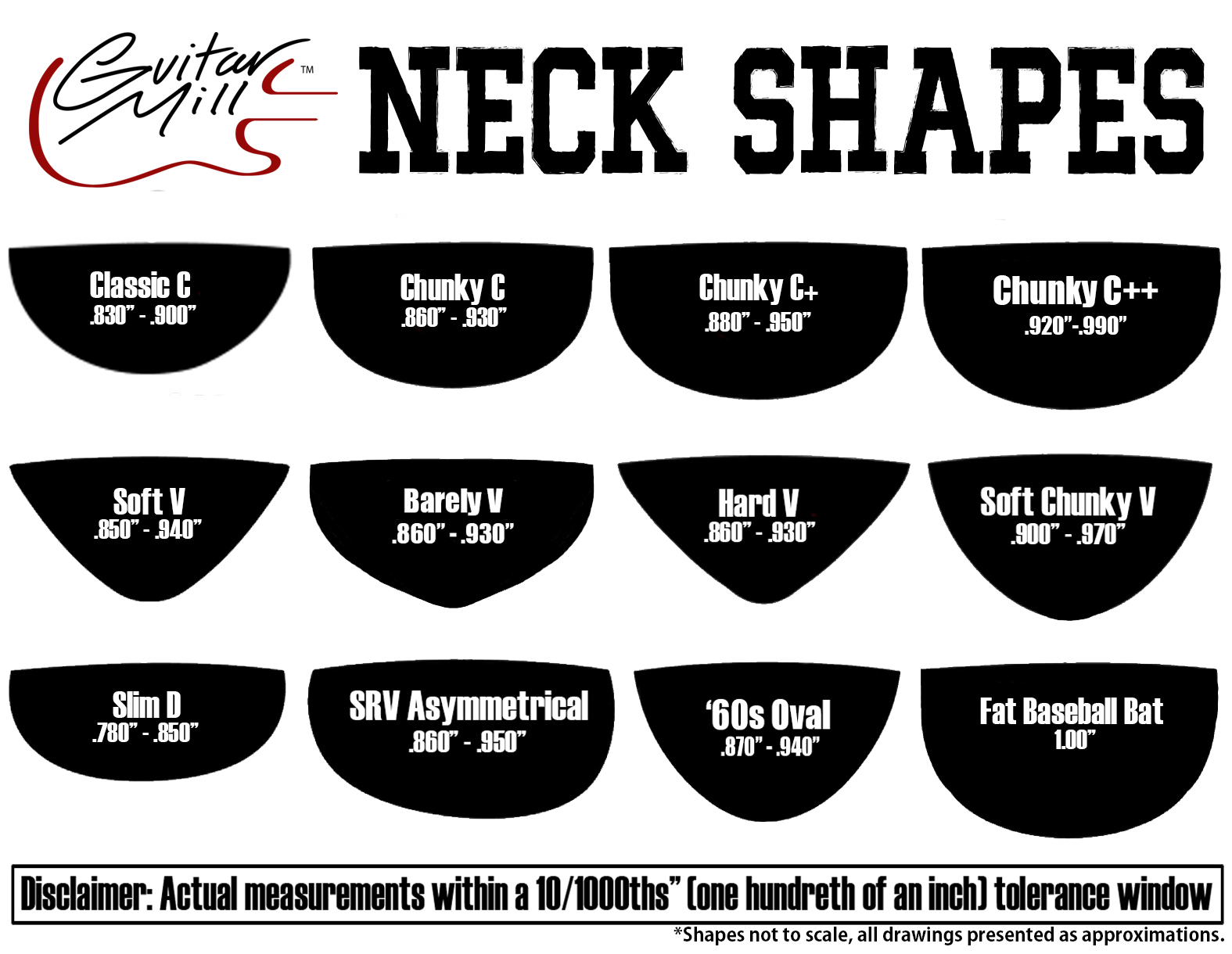

Q: What neck profile/back shapes do you offer?

A:

Q: Guitar Mill clay dots look like the real deal — are they real clay?

A: We have experimented with several different materials over time, and finally found one that most closely resembles Fender’s vintage dots. Though we can’t disclose all of our trade secrets — we will say that we are NOT using actual clay. Historically, the term “clay dots,” was only a nickname coined for the color of the original dots. Many say that the phrase “clay dots” began years later, after the inlay material aged and yellowed into the “clay-esque” color we all know today. As expected, some less-knowledgeable builders have taken the “clay” thing literally and actually use modeling clay for their dots!

Q: There are others out there selling bodies, necks and aging/relics much cheaper than Guitar Mill – What’s up with that?

A: This is something we struggle with everyday; trying to compete with small home based guys using cheap bodies they get from large, foreign, discount suppliers, factories, online auctions, etc. Though we are small as well, we — unlike most others, actually build everything in our shop. We start from scratch; going to the lumber mills and hand selecting the most premium tonewoods. So the short answer is, though we are not as large as some other manufacturers; we still do what the big guys do. That is – we build and finish everything in house. This approach may not be quite as profitable or easy as the guys buying discounted lower grade bodies and necks, but being the cheapest was never our mission. We have committed ourselves to making the highest quality vintage-correct guitars on the market today. When it’s all said and done, we like to feel satisfied knowing we have completely crafted a superior product. We hope that more people will see that we are not in the same league as “the guys selling cheap” or “The Big ‘W.'” We realize we probably miss out on many sales because we are not the “cheapest”, but we are more interested in serious players who know their gear.

Q: What is the connection between Guitar Mill, Mario Guitars and Mario Martin?

A: Guitar Mill has been a leading supplier of parts for several years now. Our premium bodies, necks and nitrocellulose finishes are being used by some of the best known builders out there. Mario Martin started Guitar Mill in 2005, and has remained at the helm as owner and leader of daily operations ever since. The Guitar Mill “Custom Shop,” was formed as a response to a growing number of requests for “fully built” custom guitars. The Guitar Mill Custom Shop was renamed Mario Guitars after Mario felt a greater need to associate his name with his world-class work. Both companies operate from the same shop; Mario Guitars referring to our full builds and Guitar Mill referring to our boutique quality replacement parts.

Check out Mario Guitars HERE!

Q: Does Guitar Mill accept returns?

A: If for some reason you are not satisfied with your purchase upon receiving it, items may be returned within a 7 day period for a refund or exchange. Keep in mind – ALL “Get It Now” items are subject to a restocking fee of 25 – 30%. These items are clearly listed with details and photographs, so if you purchase the item, and then decide you want to return or cancel the order – there will be a restocking fee. Items must be unaltered and sent back in the original condition. We will thoroughly inspect the item(s) for refund/exchange eligibility. Nitro finishes are susceptible to “cold checking,” cracking and other forms of damage that are not covered by any kind of warranty. Read more: GM Finish Disclaimer – Warranty.

ALL Refunds will incur a 25% – 30% restocking fee. Fully custom work/items (NON- GIN) are NOT eligible for refunds. Custom work is defined as up charges/add ons, services which make your body or neck especially unique and difficult to resell.

Q: What if I want to cancel my order or receive a refund?

A: Well, since most all products are custom built per your specs, if you need to cancel your custom body or neck order you WILL be responsible for its non-refundable custom work and/or a 25% – 30% restocking fee depending on the amount of custom work involved.

LEGAL DISCLAIMER : “Martin®” is a registered trademark of C.F. Martin & Co., Inc. of Nazareth, Pennsylvania, USA. Guitar Mill® is not affiliated with, endorsed, sponsored, or otherwise associated with C.F. Martin & Co., Inc.

LEGAL DISCLAIMER: Guitar Mill® is in no way affiliated with, endorsed, sponsored, licensed by or otherwise associated with the Fender® Musical Instruments Corp. of Scottsdale, AZ. “Tele®,” “Telecaster®,” “Strat®,” “Stratocaster®,” “Jazzmaster®,” “Cabronita®,” “Jaguar®,” “Mustang®,” and “Thinline®” are registered trademarks of the Fender® Musical Instruments Corp.

COURTESY DISCLAIMER: Since we are a small company, lead times are subject to change. Lead times represented on this site as an average. Actual lead time may vary due to work load, material availability, employee illness, family emergency, attention to detail, order specifics and other varying circumstances. We try our best to get every order out as quickly as possible, however, we refuse to sacrifice quality for a shorter lead time. Trust us, all of our products are well worth the wait